Hy-Grade Metal Products has been providing metal spun parts since 1918. Our experience and knowledge of the spinning process, combined with the use of CNC equipment, make us a leader in the industry.

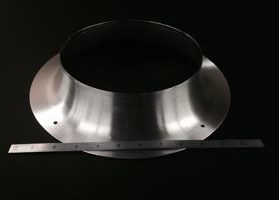

This inlet cone is used in the HVAC units of rail cars. It is essentially an air flow director for the units fan. Using 1100 aluminum, these part were sheared, circled, spun and machined to tolerances of as low as +/-.005”. After fabrication, parts are powder coated according to PSU-433-01, with a Tiger Drylac 38/91020 anodize silver topcoat.

These inlet cones have outside diameter of 12.050”, an inside diameter of 7.990” and an overall height of 2.230”. A bolt circle is machined into the offset ring after forming. Parts are visually and dimensionally inspected during the process to insure a consistent finish and the rings are to spec. We will typically provide 40-50 of these items per run. Lead times are within 4 weeks.

You can find out more information on these glare reducer assemblies below or you may contact Hy-Grade Metal by phone (315-475-4221) or email us.

Inlet Cone Fabrication Properties and Highlights

- Product Name

- Inlet Cone

- Product Description

- Used as an airflow director for HVAC purposes

- Industry of Use

- Rail Car Industry

- Capabilities / Processes

-

- Primary:

Shearing

Circle/Rotary Shearing

Spinning

Trimming

Hole Making - Secondary:

Deburring

Degreasing

- Primary:

- Equipment Used for Manufacture

- Shear

Circle/Rotary Shear

Spinning Lathe

Turning Center

- Material Used for Manufacture

- 1100 alloy Aluminum

- Overall Dimensions

- 12.050" O.D.

7.990" I.D.

2.230" height

- Tightest Tolerances

- +/- .005"

- Finish

- Raw Spun Finish

Powder coat according to PSU-433-01

Tiger Drylac 38/91020 Anodize Silver

- In Process Testing / Inspection Perfomed

- Material inspection/Gauge inspection

Dimensional inspection

Visual inspection

- Volume

- 40 – 50 pieces per run

- Turnaround Time

- 4 weeks to make tooling and order quantity

Parts are complete and ready for ship when needed at 25 per month

- Delivery Location

- Syracuse, NY – U.S.A

- Standards Met

- Per Customers Specifications

ISO 2768-cK